Selective Metal Recovery Without Excavation: A New Osmotic Path for Mining

Selective Metal Recovery Without Excavation: A New Osmotic Path for Mining

INTRODUCTION

A new generation of mining technologies is emerging, one that challenges a centuries-old assumption: that extracting metals must involve breaking rock. Drawing from breakthroughs in membrane science, nanomaterials, and fluid engineering, these methods enable the selective recovery of dissolved metals directly from subsurface formations, without drilling or excavation.

At the heart of this innovation lies a concept inspired by osmotic processes. While not osmotic in the strict biological sense, the term here refers to selective ion transport driven by pressure or concentration gradients, using advanced membranes. As these techniques move from experimental to operational, they offer a credible pathway to access critical metals with minimal surface disruption, opening the door to a fundamentally different kind of mining by the end of this decade.

A TECHNOLOGY ROOTED IN WATER SCIENCE AND NATURAL PROCESSES

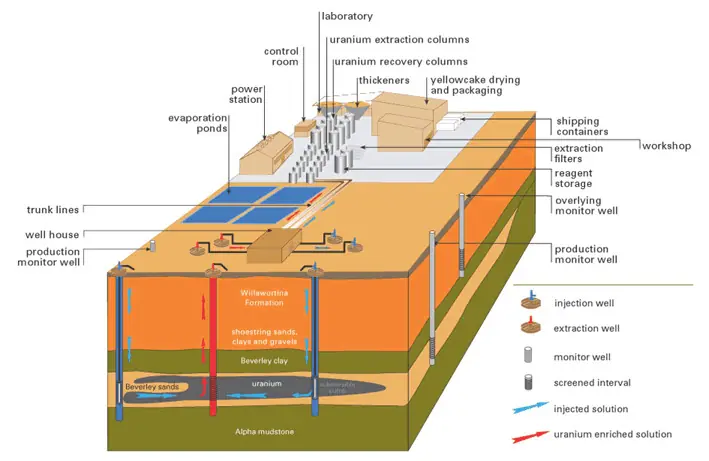

Mineral recovery via osmotic principles, where metal ions migrate through semi‑permeable membranes under pressure or osmotic gradients, is already in use for lithium extraction from brine (e.g. NREL 2021 Direct Lithium Extraction Report) and adapted experimentally to geological formations. Studies commissioned by CSIRO in Australia explore in‑situ recovery (ISR) techniques for rare earths and base metals with low disturbance and cost.

The public releases by CSIRO and Cobra Resources validate pilot ISR methods in Australia’s Boland project using low‑cost, minimally invasive in-situ recovery cobraplc.com.

Further, MDPI’s review of in‑situ leaching techniques (ISL), particularly for uranium, confirms its status as a low-impact, cost‑effective alternative to excavation mining www-pub.iaea.org.

TRIPLE DISRUPTION : ENVIRONMENTAL, ECONOMIC & GEOPOLITICAL

Environmental Impact

- No excavation or tailings ponds: ISR/ISL approaches eliminate the need for open pits and tailings management. According to comparison articles (Discovery Alert, 2025), ISL can reduce surface disturbance by 85–90% compared to conventional mining.

- Lower emissions: Those same studies estimate ISL processes may produce up to 70% less greenhouse gases by skipping diesel‑powered earthmoving machinery.

Economic Impact

- Lower capital and operational cost: In-situ leaching (ISL) eliminates the need for extensive surface infrastructure such as pits, crushers, and tailings dams, leading to significantly reduced capital expenditures. According to the International Atomic Energy Agency (IAEA), ISL operations typically require 30–60% lower initial investment compared to conventional mining for uranium and can offer operating cost advantages depending on geology and permeability (IAEA TECDOC‑1799, 2016).

- Recovery rates vary between 60–90%, depending on ore mineralogy and fluid flow characteristics. For example, the Boland rare earths pilot project (Cobra Resources, Australia) reported initial recovery efficiencies of 58–65% using low-impact ISR techniques designed for scalability in shallow, oxidized mineral systems (Cobra Resources press release, 2023).

- Industry reviews, such as those published in Mining (MDPI, 2023), suggest that ISR and selective membrane technologies, when combined with digital optimization tools, can result in overall cost reductions of 20–30% compared to traditional extraction methods under favorable geological conditions.

Geopolitical Impact

- Access to sensitive or urban deposits: In-situ recovery (ISR) methods enable the extraction of critical minerals from geologically favorable zones that would otherwise be off-limits due to environmental, regulatory, or land-use constraints, such as populated areas, protected zones, or sites with limited surface access. As noted by the International Atomic Energy Agency (IAEA), ISR’s minimal surface disturbance and low water usage make it particularly suitable for regions under strict environmental governance.

- Strategic diversification of supply: ISR offers a potential route for reducing geopolitical dependence on traditional extractive hubs. For example, Cobra Resources’ Boland Project and Broken Hill Cobalt Project in Australia aim to produce rare earth elements and battery-grade cobalt, respectively, using low-impact, localized recovery methods. These initiatives align with broader efforts to diversify supply chains away from dominant actors such as China and the Democratic Republic of Congo.

- ISR could thus play a key role in re-shoring or regionalizing critical mineral supply chains, particularly in jurisdictions like Australia, Canada, or the EU, where permitting conventional mines is increasingly challenging due to public and environmental scrutiny.

INDUSTRIAL OUTLOOK (3–5 YEARS)

Technological Maturity

Recent advances in materials science have accelerated the development of ion-selective membranes based on graphene oxide and MXenes, which show high potential for separating targeted metal ions from complex solutions. A 2023 study published in Nature Reviews Materials highlights how 2D materials like MXenes offer customizable surface properties and high chemical resistance, making them promising candidates for selective ion transport in harsh environments such as those encountered in leaching circuits or osmotic recovery systems.

When integrated with in-situ recovery (ISR) techniques, these next-generation membranes could significantly improve metal selectivity, reduce reagent losses, and enable modular, low-footprint processing systems adaptable to remote or sensitive mining environments.

Digital Convergence

The integration of reactive transport modeling and AI-based control systems is becoming essential for optimizing in-situ recovery (ISR) operations. A 2023 open-access article published in Mining (MDPI) outlines how digital twin frameworks enable real-time monitoring of hydraulic flow, pH variation, reagent diffusion, and recovery kinetics in uranium ISR settings. These digital models support predictive decision-making and significantly reduce environmental risks through adaptive process control.

Such tools, when adapted for other metals, pave the way for automated osmotic mineral recovery, especially in heterogeneous or fractured geological environments.

Regulatory & Financial Support

While reverse osmosis ISR is still emerging, the in-situ leaching (ISL) model for uranium mining provides a robust regulatory precedent. According to the International Atomic Energy Agency (IAEA), ISL is recognized as a lower-impact mining method requiring Environmental Impact Assessments (EIA), hydrogeological modeling, and strict monitoring protocols. The IAEA’s 2016 technical report on ISR outlines best practices for minimizing aquifer contamination and enforcing post-mining site remediation.

These internationally recognized guidelines offer a foundational framework for adapting similar environmental governance to non-radioactive critical metals, particularly in jurisdictions aiming to balance mineral development and ecological integrity.

CONCLUSION

The recovery of metals without excavation, through membrane-assisted in-situ methods, is no longer a theoretical concept. Grounded in advances in materials science and field-tested through early-stage pilots, it now represents a credible alternative to conventional mining, particularly for low-grade, scattered, or environmentally sensitive deposits.

By drastically reducing surface disturbance, water use, and infrastructure requirements, this approach opens new possibilities for producing critical minerals in regions where traditional mining is no longer viable or acceptable. It also offers an opportunity to rethink how extraction can align with environmental constraints and geopolitical priorities.

To move forward, the focus must shift from experimentation to deployment. This will require greater coordination between industry players, researchers, regulators, and financial actors, each playing a role in shaping a new generation of mining practices that are both effective and aligned with the expectations of our time.

Articles similaires

Former des géologues pour comprendre le sous-sol… ou pour décider avec lui ?

Le sous-sol invisible : quand la donnée géologique devient un actif géopolitique

Réserves Minières : Les décideurs face à l'épreuve de l'incertitude géologique

Formation et Renforcement des Capacités : ESG pour le secteur minier de la RDC

Géoécriture : pour une souveraineté géoscientifique du 21e siècle